The Impact of Digital Twin Technology on the Energy Industry: Opportunities and Challenges

Digital Twins – Introduction

Definition and explanation of Digital Twin Technology

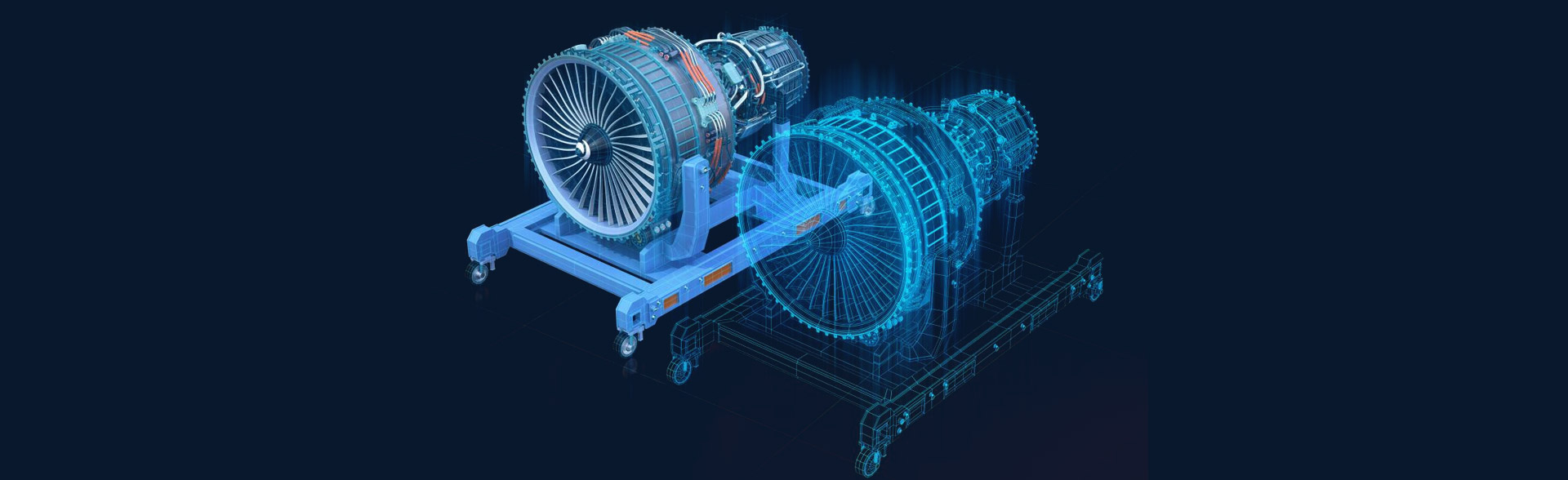

Digital Twin Technology (DTT) is the final frontier for digital innovation. Digital Twins are computer-generated model replicas of physical objects used to simulate and analyze the attributes and functions of real-world entities. This technology has become increasingly vital for optimizing complex energy system operations, allowing for continuous monitoring with predictive insights that enable organizations to assess and plan for future events or developments. Furthermore, Digital Twin Technology keeps improving; it has revolutionized every aspect of the energy industry, from data management to customer experience. Digital Twins provide an ingenious solution to the energy industry’s many problems – making it easier than ever to ensure safety and smooth operation.

How Digital Twins are different from other technologies like Virtual and Augmented Reality

Digital Twin Technology is the tech-futuristic concept that is making waves throughout the energy industry, and it has been compared to other technologies like virtual reality and augmented reality. However, Digital Twins are far more than a typical VR or AR tool – Digital Twins are both real-time and proactive. DTT combines the “Big Data” with AI algorithms to create an exact digital representation of a physical asset or system that simulates operations and monitors performance. Digital Twins track and report information, detect anomalies, and provide insights for improved efficiency and decision-making. In this way, Digital Twin Tech truly stands out from other technologies!

Impact of Digital Twin Technology on the Energy Industry

The potential for Digital Twins to revolutionize energy management and provide real-time data

Digital Twins are beginning to revolutionize the energy industry with their integrated sense-and-respond capabilities. Digital Twin Technology enables real-time monitoring of energy outputs and improves the efficiency of entire systems by predicting failure rates, potential problems, and solutions. By applying Digital Twin data to existing infrastructure, decision-makers within the energy industry can identify elements that require attention before an issue arises, gaining visibility into a new level of real-time insight. Digital Twins could soon become an integral part of managing the demand for energy resources in smart cities and other high-energy-consuming areas. With the Digital Twin revolution well underway, the benefits of increased efficiency and cost savings make it clear that this evolving technology can potentially improve the modern energy landscape.

How Digital Twin Technology can help optimize renewable energy sources and reduce downtime

This technology has the power to transform the renewable energy sector and make things much more efficient. A powerful tool that enables accurate simulations of renewable energy systems, allowing engineers to test and optimize systems before they go live. It can also help identify weaknesses in existing systems quickly and predict potential problems before they occur, allowing engineers to stay ahead of the curve in optimization and prevent lengthy downtime. Digital Twins enable monitoring renewable energy assets as they run, giving engineers data-backed insights on why a system might not perform optimally. It is an excellent opportunity for any organization aiming to reduce downtime and ensure their renewables run as efficiently as possible.

Opportunities for Digital Twins to improve operational efficiency, cost savings, safety, and sustainability in the Energy Industry

Digital Twins allow Energy companies to monitor and optimize the performance of their entire value chain in real time, from production to consumption. With Digital Twin Technology, renewables such as solar and wind farms are monitored more accurately than ever, helping Energy companies predict outputs more accurately and meet demand quickly when necessary. Additionally, Digital Twins can provide a virtual environment to simulate potential outcomes of changes in operations or policies before implementation in the physical world, ensuring success and reducing risk.

Benefits of Digital Twin Technology in the Oil, Gas, and Renewables Industries

• Efficiency and cost savings – Digital Twins simulate processes virtually before implementation.

• Provide real-time data on the performance of systems in the energy industry, which helps increase safety and reliability and reduce wastage.

• Plan for future operations by analyzing past operational data and predicting potential problems, which allows executives to make informed decisions about their energy investments.

• DTT-powered analytics also help identify areas where efficiency improvements could be made, such as resource allocation or process optimization, ultimately leading to improved profitability.

Challenges posed by Digital Twins, such as integration into existing systems and accuracy of data collecting

Despite its potential benefits, Digital Twin Technology also comes with some challenges for the Energy Industry:

• Digital Twin Technologies require significant investments in infrastructure and data processing capabilities to develop effective Digital Twins.

• Digital Twins’ analytics also requires proper training and expertise to interpret the data correctly. It can pose a challenge as it requires specialized personnel or costly consultants.

• Managing the balance between traditional processes and digital technologies is still challenging for many energy companies transitioning from analog to digital operations.

• Security is also an issue since Digital Twins typically rely on large datasets, which makes them vulnerable to malicious attacks.

Overall, Digital Twin Technology is a powerful tool that can help energy companies optimize operations and more accurately manage their investments. However, the success of Digital Twin technology in the Energy Industry depends on how companies can address the challenges mentioned above. With proper implementation and training, companies can use Digital Twins to provide valuable insights and increase efficiency in the Energy Industry.

Use Cases of Digital Twin Technology in the Oil, Gas, and Renewables

Drilling and Exploration

Digital Twins analyze real-time data from drilling sites, allowing engineers to assess safety risks and optimize operations.

• Asset performance: Digital Twins allow energy companies to monitor and analyze their assets in real-time, providing insights into their performance. It helps ensure investments are efficient, leading to cost savings.

• Supply chain management: Digital Twin Technology enables Energy companies to identify supply chain bottlenecks and analyze changes’ potential outcomes before implementation. It allows them to make informed decisions about resource allocation or process optimization, which results in improved efficiency.

Renewables Energy

• Predictive maintenance: Digital twins enable engineers to predict potential maintenance issues and plan for preventive maintenance before any problems occur, help reduce downtime and keep operations running smoothly.

• Optimizing energy production: Digital Twins can analyze real-time data from renewable sources and identify areas where efficiency improvements could be made, such as resource allocation or process optimization.

• Smart grid integration: Digital Twins can help integrate renewable energy sources into existing grids, providing insights into utilizing renewable energy within the existing infrastructure.

Reservoir management

Digital Twins offer unparalleled insight into reservoirs for the oil and gas industry – from simulation of fluid flow in a reservoir to predicting production performance. This insight is invaluable, allowing them to optimize processes and maximize returns in an incredibly competitive market. Digital Twins use simulations, data acquired from sensors, computational models, and artificial intelligence algorithms to create faithful digital replicas of physical objects in real time. These Digital Twins can monitor various activities across the entire asset lifecycle in oil and gas reservoirs, enabling them to detect anomalies quicker and more accurately than ever.

Production and Operations

Digital Twins allow production and operations to be monitored with impressive accuracy, provide predictive insights into maintenance issues, and determine minimum energy consumption during peak and non-peak periods. DTT is especially beneficial to the energy and oil and gas industries and can significantly reduce downtimes thanks to their features, like virtual simulations, analytics, and tracking of digital twins within environments such as renewable wind turbines or any other asset within the respective infrastructure. It ultimately helps lead to more productive operations while offering additional eco-friendly benefits.

Refining and Petrochemical Processing

Digital Twin Technology is revolutionizing the energy refining and petrochemical process. It can drastically reduce risks associated with hazardous materials in refining, enhance worker safety, predict maintenance needs, and identify operating inefficiencies. Digital twins can even help streamline billions’ worth of capital investment decisions across many facets of the refinement process, such as engineering, design, and construction. Digital Twins leverage connected technologies to simulate and analyze complex networks of refining and petrochemical facilities for risk management, operations planning, and streamlining workflows that may be tedious or dangerous in other ways. Digital Twin Technology makes these processes more intuitive and saves time and resources – two things any company would be wise to consider. Another reason why Digital Twins are becoming increasingly vital as the global energy market continues to evolve.

Wind and Solar Power Generation

Most notably with Wind and Solar power generation, DTT has enabled frequent real-time analytics of energy generation and system performance to make precise adjustments for better efficiency, reliability, and cost-effectiveness. Digital Twins are being used to streamline wind farm installation, testing, operation, maintenance, and repair costs. Similar applications are visible with solar power projects where Digital Twins work harmoniously with Digital Threads to maximize the output potential of the panels themselves while ensuring that more efficient parameters are available during operations. Digital Twins provide a revolutionary way to generate more reliable renewable energy sources without being physically present on location, creating new possibilities and opportunities across the globe.

Battery Storage and Microgrids

Using Digital Twin Technology to model real-world scenarios, stakeholders can optimize the production of solar and wind energy and refine the storage and distribution of renewable resources like battery storage and microgrids. Microgrid Digital Twins have gone further than traditional DTT simulators by providing granular data about system dynamics, components, and customers. It enables customers to monitor their energy usage better and identify inefficiencies that may be rectified or avoided with more intelligent resource management. Digital Twins also provide visibility into current operations so decision-makers can determine how best to adjust their resources to maximize the benefits of technology while minimizing risk.

Predictive maintenance and performance optimization

DTT enables predictive maintenance and performance optimization, helping extend the life of machines while keeping them running at peak efficiency. Digital Twin Technology tracks metrics like energy consumption by working with exact digital clones of machines. It identifies areas of underlying weakness before they become an issue, meaning maintenance and repair can occur before breakdowns occur, saving time and money.

The future outlook for using Digital Twin Technology in the Oil, Gas, Energy, and Renewables Industries

In conclusion, Digital Twin Technology has opened up new opportunities for companies in the Oil, Gas, Energy, and Renewables. By utilizing this technology to gain greater real-time visibility and control, companies can develop better solutions for their respective markets and increase operational efficiency. As the possibilities of what a DTT can be applied to continue to expand, it will become even more valuable for taking advantage of new energy resources. With the emergence of artificial intelligence and machine learning many aspects of the energy industry will see tremendous advancements soon. It’s an exciting time to be involved with these industries as they look towards digital twins to power research initiatives and help them carry out complex analyses that weren’t previously possible.

If you want to learn more about how Digital Twins can help your organization, IMMIX Productions can help. We have an extensive background in the Oil, Gas, Energy, and Renewables Industries. Let’s work together to develop Digital Twin Models and Applications tailored to your company’s needs, help streamline your process, and improve efficiency with Digital Twin Technology.