Article 1: Unlocking the Potential of VR in Lockout Tagout Training

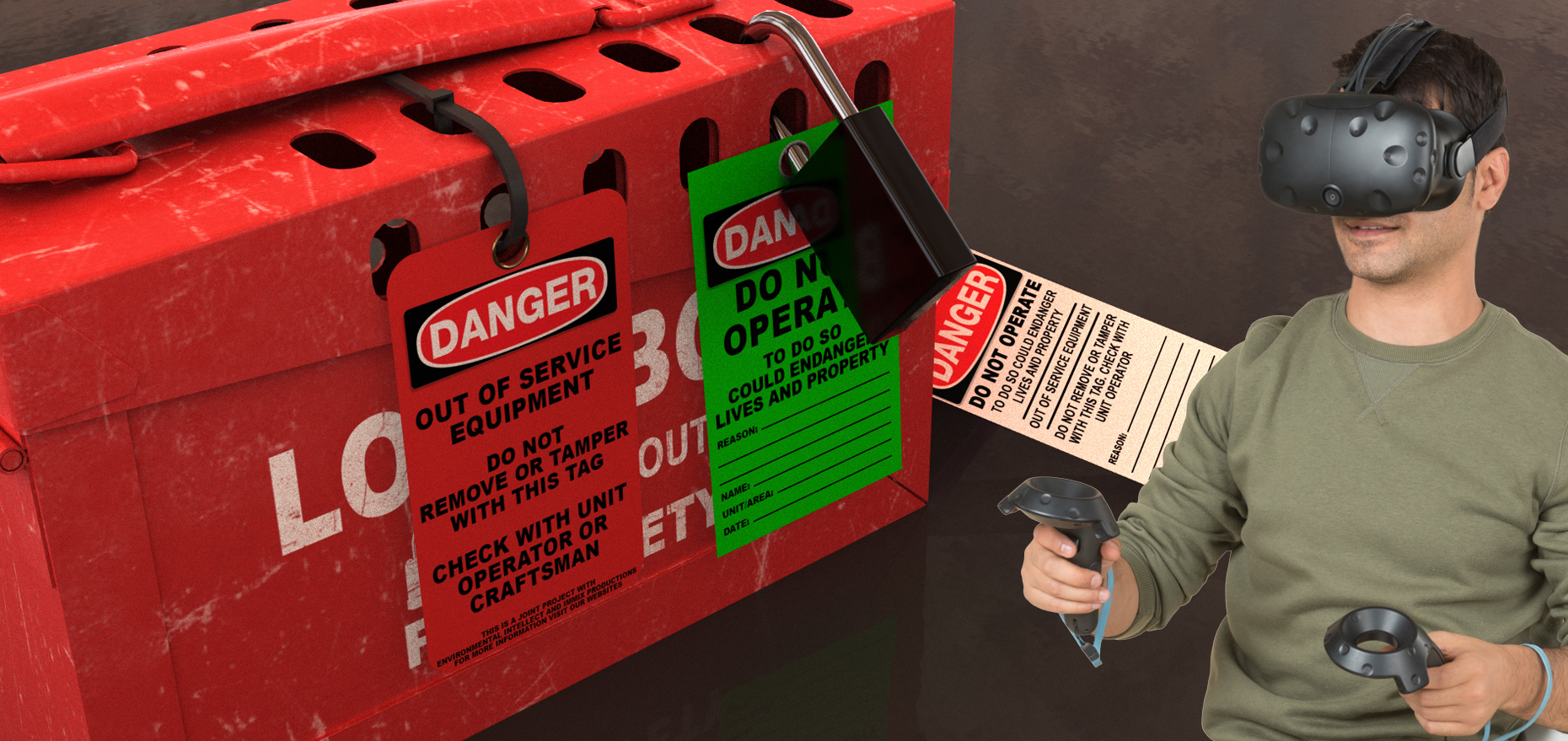

With the rapidly evolving landscape of industrial safety training, Virtual Reality (VR) technology is at the forefront of a revolutionary shift, especially in Lockout Tagout (LOTO) procedures. This cutting-edge approach provides an immersive learning environment, offering employees hands-on experience dealing with hazardous energy control without the associated real-world risks. IMMIX PRODUCTIONS is leading this change through detailed simulations by developing realistic virtual environments where employees can safely encounter various workplace scenarios. This approach enhances learning outcomes and actively engages employees in learning, making it more effective and memorable. In a series of three articles on IMMIX LEARN, we will explore how VR transforms LOTO training to provide workers with a more engaging, effective, and realistic learning experience.

The Next Frontier in Worker Safety: How VR is Transforming LOTO Training

As technology advances, so too do the ways we can ensure workers’ safety and well-being. Safety training, especially involving intricate and life-preserving procedures such as Lockout Tagout, has always thrived on the principles of hands-on learning and spatial awareness. Virtual Reality (VR) is the modern-day savior to simulate such realistic conditions in a safe and controlled environment.

Here’s how VR is forging new frontiers in LOTO training:

Interactive VR LOTO Training Scenarios

With VR technology, LOTO training can go beyond static visual aids into dynamic, interactive experiences. Lifelike virtual environments allow trainees to practice LOTO procedures, closely replicating real-world scenarios. Immersing workers in these interactive environments make learning experiential, thus enhancing their retention and understanding of LOTO principles.

In these interactive VR LOTO training scenarios, workers can engage in various simulated conditions that could be hazardous in real life. For instance, they can experience locking out electrical panels, machinery, or piping systems without the risk of physical harm. The virtual environment can include common workplace hazards, such as electric shocks or mechanical failures, allowing trainees to learn the correct response in high-risk situations without facing the dangers.

This method is especially beneficial because it will enable workers to learn from their mistakes consequence-free, reinforcing the proper practices and procedures. VR technology can adapt to replicate specific workplace environments, making the training experience highly relevant and directly translatable to the trainee’s daily tasks. This customization and realistic practice level is unprecedented in traditional training methods and marks a significant leap in safety training.

Enhanced Realism and Practical Repetition

The enhanced realism and practical repetition supported by VR technology cannot be overstated. This immersive environment goes beyond traditional learning by allowing users to interact with a virtual world that closely mirrors the complexities and nuances of real-life scenarios. Through repeated practice, workers familiarize themselves with the steps required in LOTO procedures and build confidence in their ability to execute these actions under pressure. The tactile feedback VR controllers provide helps muscle memory formation, ensuring that the correct procedures become second nature to the practitioners.

Workers can ‘lock out’ and ‘tag out’ equipment using VR controllers, mimicking the exact gestures and steps they would perform on the field. This level of practical repetition in a risk-free setting is unprecedented and invaluable when preparing workers to carry out these procedures safely and correctly.

Additionally, instantly resetting and repeating scenarios in the VR setting reinforces learning outcomes, enabling users to practice until they achieve perfection without wasting physical resources or risking safety. This methodological repetition under realistic conditions ensures a higher competency level among workers, significantly reducing the likelihood of accidents and errors in actual workplace environments.

Risk-Free Training for Hazardous Environments

The innovative approach of risk-free training for hazardous environments through VR transforms the safety culture within industries. Training within actual hazardous environments typically carries inherent risks to the learner, the equipment, and the facility. However, VR training circumvents these dangers, allowing for a simulated, high-fidelity experience of a worker’s most difficult situations. This aspect of VR training is particularly vital in industries where the margin for error is minimal, and the consequences of mistakes can be disastrous.

For example, a wrong move could lead to catastrophic outcomes in the chemical manufacturing industry. VR training enables workers to encounter these scenarios virtually, applying their knowledge in high-pressure situations without the real-life threat of causing a chemical spill or explosion.

Exposing workers to hazardous environments virtually eliminates the risk of injury. Workers can learn without jeopardizing their safety or operations. This controlled environment allows trial and error without real-world consequences, helping to hone their skills and build confidence.

Furthermore, this training mode supports an iterative learning process, where mistakes are valuable learning opportunities rather than costly or dangerous mishaps. Workers can repeat scenarios as often as necessary to master the skills, building competence and confidence without physical risk. This safety-first approach protects the workers and ensures the integrity of the equipment and the facility, resulting in a safer, more efficient workplace environment.

Identifying Hazardous Energy Sources

In VR-based LOTO training, identifying hazardous energy sources becomes an interactive and immersive learning experience. Trainees are thrust into virtual environments to visually inspect machinery and equipment to pinpoint potential energy hazards, such as electrical, mechanical, hydraulic, pneumatic, chemical, and thermal energy sources. This training component sharpens trainees’ abilities to recognize energy sources that may take time to become apparent in a complex industrial setting. Utilizing VR for this purpose allows for a broader range of scenarios than can be safely replicated in a traditional training setup, including rare or industry-specific situations that workers might not otherwise encounter until faced with a real-world emergency.

One of the foundational pillars of LOTO training is identifying energy sources that could pose a hazard. VR simulations present a variety of equipment and energy sources, challenging trainees to identify and isolate them correctly. Thus, they promote heightened awareness and risk assessment skills in workers.

By navigating these virtual scenarios, trainees can develop a keen eye for detail and a comprehensive understanding of the diversity of energy sources they might encounter on the job. This vital knowledge forms the backbone of effective LOTO procedures, ensuring that workers in the field are equipped to identify all potential hazards and contribute to a safer workplace environment.

Cognitive Skill Development

Through immersive VR training, workers recognize and respond to hazardous energy sources and develop critical thinking and decision-making skills. Engaging in simulations challenges them to assess situations rapidly and respond appropriately, mirroring the pressures and demands they will face in real-life scenarios. Cognitive training enhances their ability to process information, prioritize actions, and execute complex procedures under stress. It is particularly beneficial in fostering situational awareness, enabling workers to anticipate and mitigate potential risks before they escalate into real-world incidents.

Through these challenges, workers sharpen their cognitive abilities, training their brains to be highly sensitive to spotting potential energy hazards. Immersive VR training becomes especially effective for workers moving into unfamiliar territory within the industrial setting.

Additionally, regular exposure to VR simulations aids in memory retention and recall, ensuring that safety protocols become second nature to the workforce. By continuously adapting to new and challenging environments in VR, workers cultivate a proactive mindset toward safety, becoming more adept at identifying hazards and navigating through emergencies with confidence and precision.

Transforming Workplace Safety with VR: The IMMIX Advantage

The safety of workers in industrial settings has taken a giant leap forward with the integration of Virtual Reality (VR) technology, particularly in the practice of Lockout Tagout (LOTO).

IMMIX Productions stands ready to assist businesses aiming to elevate their safety training programs and prepare their workforce for the complexities of modern industrial environments. Our tailored VR training solutions offer an engaging, effective, and efficient way to conduct safety training that resonates with employees and adheres to the highest standards of safety protocols. Contact us today to explore how our VR LOTO training programs can revolutionize your company’s safety training efforts. Visit: https://immixproductions.com/

#VRTraining #SafetyFirst #LOTO #IndustrialSafety #VirtualReality #WorkplaceSafety #TechnologyInSafety #InnovativeTraining #VRInEducation #SafetyTraining #EnergyControl #LockoutTagout #FutureOfWork #TechInnovation #SafetyCulture #SafetySolutions #ImmersiveLearning #IMMIXproductions

You may like these related articles on IMMIX LEARN: